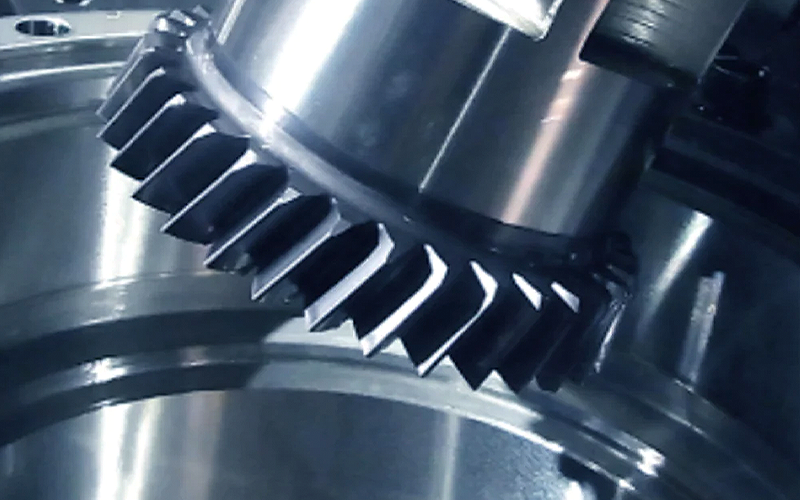

SKIVING MACHINES

Gear Skiving and Power Skiving Cutters

Gear Skiving and Power Skiving Cutters

Federal Broach and Machine is a leading distributor of precision gear skiving tools (also called skiving cutters). The use of advanced substrate material and specific coatings delivers high tool life and efficiency to the skiving process.

Gear Skiving and Power Skiving Cutter Specifications:

- Module: 0.3 to 10

- Maximum OD: 230mm

- Shank Type: 70mm

- Maximum Length: 70mm

- Shank Type: 180mm

- Bore Size: 12.7mm to 63.5mm

- Helix Angle: 0° to 35°

The Gear Skiving Process

Gear skiving, sometimes referred to as gear scudding, was developed over 100 years ago. Presently, it has become a viable manufacturing process with the optimization of new rigid and precise CNC machines that can synchronize the movements with high accuracy.

There are numerous unique skydiving processes, including power skiving and gear shaping (same tool geometry) or hard hobbing (also called skiving). Power skiving is a very fast process used to generate gear teeth – it combines principles of turning, hobbing, shaping and shaving. There is a cross-axis angle between helix angle of the part and helix angle of the tool, as in shaving cutters. This principle helps obtain a very low surface roughness with a high quality finish up to DIN 5 class.

What Is Gear Skiving and Its Advantages?

Gear skiving is a continuous cutting process that enables machining to be carried out in a single setup. The possibility to machine the complete component in a multi-task machine or machining center in one single set-up shortens production time, improves quality and reduces handling and logistics costs.

Advantages of Gear Skiving Tools

- Cycle time reduced by about 80% compared to gear shaping

- Pressure angle correction, tooth profile, and tooth thickness can be adjusted without cutter correction

- Our original design improves the tool life while maintaining work accuracy

Precision Skiving Tools for Gear Cutting Operations

Federal Broach manufactures precision skiving tools engineered to accommodate your production requirements. Our custom tooling includes gear skiving tools for precision gear cutting operations.

Based in Central Michigan, our 96,000 square-foot facility utilizes some of the industry’s most capable CNC technology and CAD systems to develop a truly optimized tooling solution for your application. Our company is an ISO 9001:2015-certified American manufacturer dedicated to delivering superior tooling for your production line.

Contact Us Today

Contact us today to learn more about our effective and dependable solutions for your projects.

We look forward to working with you and delivering exceptional results.