INTERNAL BROACH

Vertical Pull-Down Broaching Machine

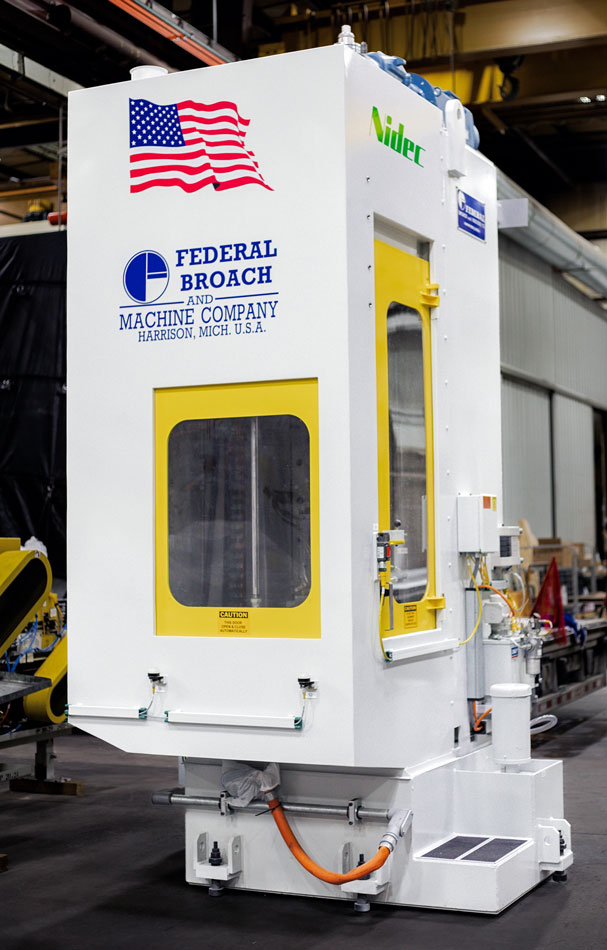

Vertical Pull-Down Broaching Machine

Federal Broach’s turnkey Vertical Pull-Down broaching machines are offered in hydraulic configurations with pull-down tables. These highly flexible machines can produce various internal profiles such as parallel sided, involute splines, cam forms and various other internal profiles. Our selection of vertical pull-down machines are available in tonnage capacities ranging from 5 to 75 tons, with strokes up to and including 120 inches.

Facility Requirements

Smaller vertical pull-down broaching machines can typically be installed on a standard concrete industrial floor. However, larger machines, such as 25 ton 100 inch stroke models, will require a 12-inch, steel-reinforced foundation. Vertical pull-down machines require approximately 300 square feet of floor space and up to 25 feet of ceiling height if equipped with an optional tool change crane. Exact specifications will be supplied due to the large variation of machines offered in this style.

Vertical Pull-Down Broach Machine Specifications:

- Machine Stroke – 24 to 102 inches

- Broach Force – 5 to 75 US tons

- Cycle time – 18 to 60 seconds

- Broach Tool Length – 24 to 102 inches

- Broach tool type – Conventional or spiral design

- Cutting speed – Variable up to 45 feet/min.

- Return speed – Variable up to 60 feet/min.

- Hydraulic system – Up to 400 US gallons(If required)

- Pneumatic system – 60 p.s.i. (if required)

- Coolant system – Self-contained, integral or pump back compatible

- Electrical system – Siemens, Fanuc, Num, or Allen Bradley

- Lubrication system – 200 hour before refill

- Part fixture design – Manual/robot shuttle table or auto load

- Machine Weight – Up to 50 tons

- Machine height – Up to 30 feet

- Floor space – Flexible design

- Foundation requirements – Up to 12-inch, steel-reinforced concrete

Standard Features:

- Fabricated steel frame – normalized prior to machining for increased durability

- Hardened and ground steel slideways (main and handling)

- Cast iron handling slide and main ram

- Hydraulic handling slide drive

- Positive puller and retriever locking

- Isolation mounts to assure stability for the broaching process

- Dry floor guarding to suit integrated load/unload systems

- Shed plates which direct chips/coolant into chip conveyor or pump back

- Painted to customer specifications

Options:

- Multiple broach stations

- Optional part blow-off system reduces coolant carry-off

- Temperature-control system

- Automatic door to accommodate part loading

- Mist collector system

- Chip conveyor

- Coolant filter

Turnkey Internal Broaching Machines and Precision Tooling Solutions

Federal Broach specializes in the total engineering, manufacturing, and integration of turnkey broaching solutions including internal broach machines. Since 1952, our company has remained a leader in the commercial broaching industry through the development of innovative machines and quality tooling. Based in Central Michigan, our company operates an 96,000 square-foot facility capable of accommodating virtually any of the modern industry’s precision broaching applications.

Contact Us Today

Contact us today to learn more about our effective and dependable solutions for your projects.

We look forward to working with you and delivering exceptional results.