CONTRACT BROACHING

Contract Broaching Services and Production Broaching

Not ready to buy new capital equipment or need support in reaching new production levels? Equipped with a complete in-house production broaching line, Federal Broach and Machine stands ready to do the broaching for you. From low-volume to high-volume contract broaching projects, from one part to 100,000 or more, our precision broaching services will enable you to reliably achieve the production capacity you’re after.

Complete Production Broaching Services:

With robust 50-75 ton broaching force capabilities and a wide range of 60-109 inch tool length capacities, our vertical rising table offers the versatility to accommodate virtually any precision broaching application for both helical and straight spline. Equipped with flexible fixture designs and full turnkey automation capabilities, these machines are truly an asset to your production line.

- Surface Broaching (racks, brake calipers)

- Internal Broaching (spline, gear, helical, ball spline, cam)

- Blind Hole Broaching

- Pot Broaching

The Advantages of Production Broaching:

- Multiple machining operations are effectively replaced by broaching, simplifying the overall production process.

- Most other metalworking processes generate extensive heat while machining the workpiece, which can create thermal stress and dimensional variation. In contrast, the broaching process does not heat the workpiece to nearly the same extent.

- There are numerous methods for both internal and external broaching operations, making it easier to achieve an optimized manufacturing process for many types of complex components.

- Broaching services can produce precision components with high-quality surface finishes, reducing the need for various secondary operations.

- Compared to many other manufacturing methods, broaching is a relatively simple process, minimizing the need for highly skilled labor and the associated costs.

An Overview of Production Broaching: Advantages and Applications

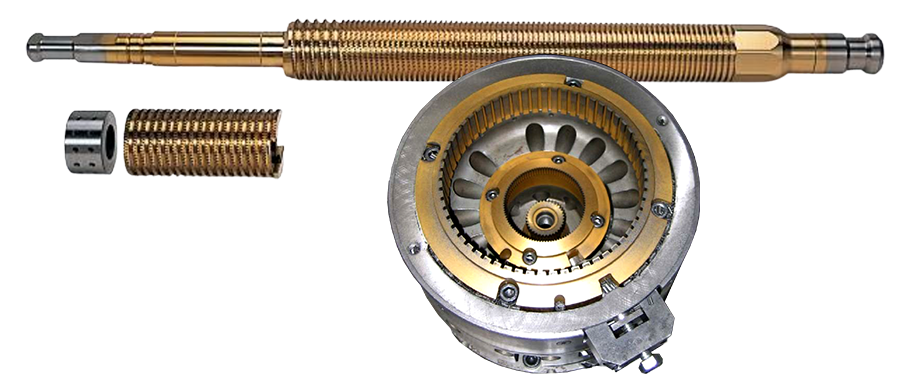

The machining process known as broaching uses a toothed tool, called a broach, to remove material. A broach is similar in looks to a saw and contains three sections: roughing, semi-finishing and finishing.

Each tooth on the broach has a different rise, or height, that determines the amount of material removed from the material. The feed is built right into the tool and a sequence is created that makes it an all-in-one production process, reducing the margin of error.

Broaching is the most reliable production solution for a wide range of precision machining applications. Even though broaches can be expensive to produce, especially custom broaches, it is usually favored over other processes due to the efficiency and quality of the finished product.

High production rate and low cycle, broaching operations are faster than other metal cutting operations lowering the price per piece for broaching.

Custom Broaching Solutions and Contract Manufacturing Services

Federal Broach provides highly efficient production broaching services. Our complete in-house broaching department is capable of streamlining your project from start to finish and simplifying your supply chain.

Contact Us Today

Contact us today to learn more about our effective and dependable solutions for your projects.

We look forward to working with you and delivering exceptional results.