POT BROACHING

Pot Broaching Machine

Pot Broaching Machine

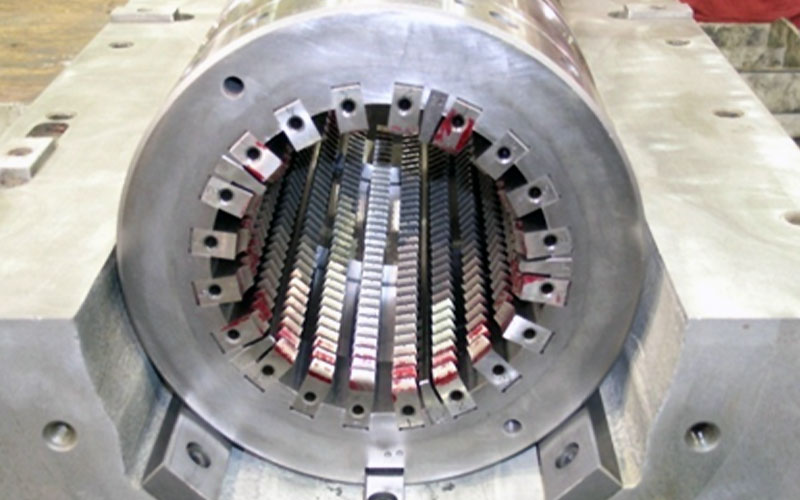

Offered in electromechanical or hydraulic styles, our pot broaching machines can produce various external profiles such as parallel-sided, involute splines or cam forms and various other shapes. Federal Broach’s pot machines come in tonnage capacities from 5 to 50 tons and strokes up to and including 78 inches.

Facility Requirements

These machines usually can be installed on a standard concrete industrial floor, however, larger machines such as a 35 ton 78 inch stroke model will require a 12-inch, steel-reinforced foundation. Pot machines require approximately 400 square feet of floor space and up to 25 feet of ceiling height if equipped with an optional tool change crane.

Pot Broach Machine Specifications:

- Mechanical or hydraulic operated main ram

- Machine Stroke – 36 to 78 inches

- Cutting Tool assembly length – 34 to 76 inches

- Broach Force – 5 to 50 tons

- Cycle time – 12 to 30 seconds

- Broach tool design – Multi-piece array, customized for number of external splines

- Cutting speed – 30 feet/min.

- Return speed – 60 feet/min.

- Hydraulic system – 350 US gallons (if required)

- Coolant system – Self-contained (300 gallons) or can be integrated to pump back or central system

- Pneumatic system – 60 p.s.i. (if required)

- Electrical system – Siemens, Fanuc, Num, or Allen Bradley

- Up to 200 amp disconnect (hydraulic)

- Up to 400 amp disconnect (mechanical)

- Lubrication system – 200 hour capacity before refill (if required)

- Part fixture design – Fully automatic part handling fixture

- Machine Weight – 20,000 to 50,000 pounds

- Machine height – 12 feet to 20 feet (not including lifting hoist)

- Floor space requirements – 20’ X 20’ (400 sq. foot)

- Foundation requirements – Up to 12 inches of steel-reinforced concrete depending on the machines size and weight

Standard Features:

- Heavy, welded steel frame, thermally normalized prior to machining

- Dry sump to keep main hydraulic cylinder from contracting coolant from broach cutting oil

- Pressure-lubricated main hydraulic cylinder rod bearing

- Stand-alone flooded suction hydraulic system with main hydraulic manifold

- Heavy-duty, 3000 PSI, mill-style, head-mounted, hydraulic cylinder without tie rod

- Pneumatic system to customer specifications (if required)

- Shed plates to direct chips and coolant into chip conveyor and/or coolant system

- Coolant manifold with ball valves and nozzles

- Leveling jacks with integral anchor bolts

- Dry floor guarding

- Pick-up holes installed in machine frame

- Machine frame painted to customer specifications

Options:

- Optional part blow-off system reduces coolant carry-off

- Hydraulic drivetrain

- Automated part handling systems for multiple operation / work cell integration

- Mist collector system

- Crane and hoist system

- Integrated chip conveyor

Quality Pot Machines and Turnkey Broaching Solutions Since 1952

Federal Broach provides complete broaching machine solutions for a wide range of applications, including quality-engineered pot machines and associated tooling. Located in Central Michigan, our 96,000 square-foot facility is equipped with some of the industry’s most current CNC and CAD technology in order to accommodate the total design, fabrication, and assembly of your turnkey machining systems. Our company is an ISO 9001:2015-certified American manufacturer committed to delivering the precision, superior quality, consistency, and on-time delivery that your custom machining project requires.

Contact Us Today

Contact us today to learn more about our effective and dependable solutions for your projects.

We look forward to working with you and delivering exceptional results.