SURFACE BROACH

Electromechanical Horizontal/Vertical Surface Broaching Machine

Electromechanical Horizontal/Vertical Surface Broaching Machine

Federal Broach’s highly flexible surface broaching machines are offered in electromechanically driven, bidirectional single ram versions with custom (per application) designed fixtures and mounting knees. Properly equipped, these machines can produce various profiles such as aircraft turbine fir tree slots, turbine fan blade root forms, steering racks, main bearing cluster for diesel engines and various other external profiles.

Our surface broach machines come in tonnage capacities up to 50 tons and strokes up to and including 360 inches. Almost all of these machines are installed on custom-designed foundations to insure dimensional stability and to isolate them from outside vibration.

Horizontal/Vertical surface broaching machines exact specifications will be supplied with machine quotations due to the large variation in application and size.

Surface Broach Machine Specifications:

- Machine stroke – Up to 360 inches

- Broaching force – 20 to 50 US tons

- Cycle time – Varies depending on application and stroke

- Lubrication system – Automatic 200 hours

- Broach tool length – Up to 300 inches/pass

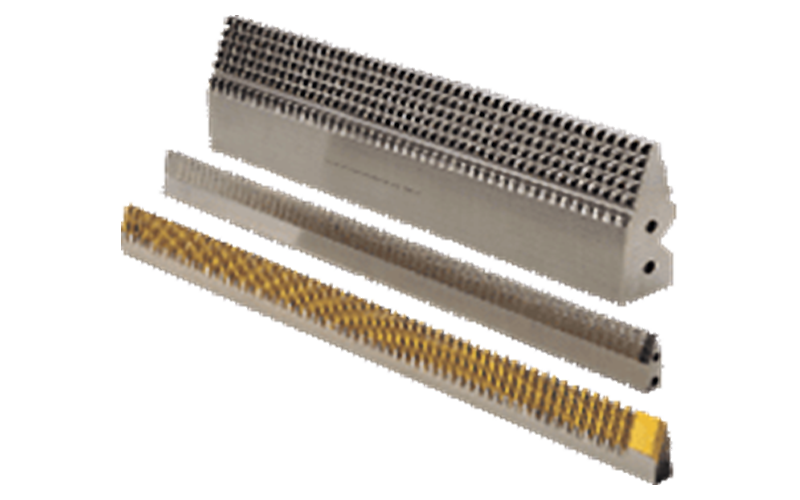

- Broach tool type – High-speed steel or carbide

- Cutting speed – Variable up to 100 feet/min when using carbide cutters

- Return speed – Variable up to 100 feet/min.

- Hydraulic system – Up to 50 US gallons (if required)

- Pneumatic system – 60 p.s.i. (if required)

- Coolant system – Self-contained

- Electrical system – Siemens, Fanuc, Num, or Allen Bradley

- Main ram drive – Rack and pinion through a gear reducer

- Fixture mounting knee – Custom design

- Part fixture design – To suit application

- Machine weight – Up to 200 tons

- Machine Height – Approximately 15 feet

- Floor space – Flexible design

- Foundation – Custom design

Standard Features:

- Fabricated modular steel frame, normalized prior to machining

- Hardened and ground steel flat box ways

- Cast iron main slide

- Hydraulic system to suit fixture and application

- Pneumatic system to suit virtually any application

- Isolation mounts and anchors under main machine and knee

- Safety guarding to suit fixture and knee design

- Shed plates that direct chips and coolant into the chip conveyor or pump back

- Remotely positioned coolant tank

- 10-horsepower coolant pump

- Painted to customer specifications

Options:

- Can be arranged for both central and self-contained coolant systems

- Chip conveyor

- Coolant temperature control

- Coolant filter

- Run-off in our plant and customer’s facility

- Installation and start up

- Non-warranty service

- Transportation services

- Broach tool monitoring

- Automatic tool changer

- Integrated brush system to clean tools

Custom Surface Broaching Machines Engineered for Your Application

Federal Broach specializes in the development of innovative broaching solutions including custom surface broaching machines uniquely developed for your production line. Based in Central Michigan, our 96,000 square-foot facility is integrated with some of the industry’s most capable CNC technology and CAD systems. Our company is an ISO 9001:2015-certified American manufacturer committed to delivering the precision, superior quality, consistency, and on-time delivery that your custom machining project requires.

Contact Us Today

Contact us today to learn more about our effective and dependable solutions for your projects.

We look forward to working with you and delivering exceptional results.