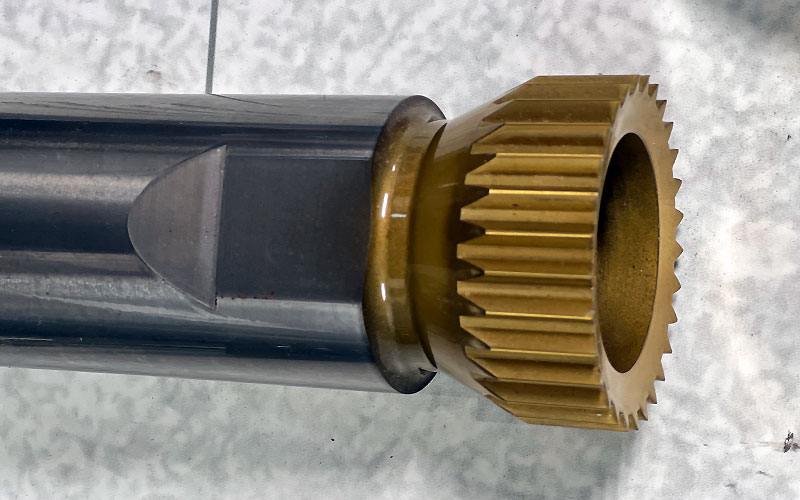

BLIND SPLINE

Blind Spline Broaching Machine

Blind Spline Broaching Machine

Offered in electromechanical or hydraulic styles, Federal Broach’s blind spline machine produces internal and external blind spines in an array of sizes and part styles. With a wide range 5-50 ton force capacity, 10-13 inch stroke capacity, and 6-26 station rotary table capacity (part design dependent), this turnkey broaching machine is a highly versatile and highly capable asset to your production line.

Facility Requirements

Typically, our relatively compact blind spline broaching machines require only 400 square feet of floor space, 12 inches of reinforced concrete, and a maximum machine height of 17 feet.

Blind Spline Machine Specifications:

- Mechanical or Hydraulic operated main rams

- Machine Stroke – 10 to 13 inches

- Broach Force – 5 to 50 tons

- Cycle time – 36 to 60 seconds

- Index table – 6 station to 26 stations (depending on part design)

- Broach tool design – Internal punch or external die

- Cutting speed – 20 feet/min.

- Return speed – 45 feet/min.

- Hydraulic system – 600 US gallons (If required)

- Pneumatic system – 60 p.s.i.

- Coolant system – self-contained (225 gallons) or can be integrated to pump back or central system

- Electrical system – Siemens, Allen Bradley, or Fanuc – 400 amp disconnect

- Lubrication system – 200-hour capacity before refill

- Part fixture design – Manual/robot shuttle table or a fully automatic part handling fixture

- Machine weight – 65,000 pounds

- Machine height – 17 feet

- Floor space requirements – 19’ X 21’(400 sq. foot)

- Foundation requirements – 12-inch reinforced concrete

Standard Features:

- Extra heavy fabricated steel machine frame – thermally normalized before machining to increase strength and rigidity

- Machine is engineered with a modular design that maximizes floor plan flexibility

- Self-contained coolant system with external tank and shed plates in machine base to direct chips out of machine and into chip filtration system

- Dry floor guarding made from 12-gauge steel with lifting doors and Lexan windows

- Epoxy filled limit switches in all coolant exposed areas

- Dual main independent hydraulic systems with separate control manifolds for each ram (hydraulically operated ram version)

- Separate motor drives and controls for electromechanical versions

- 3000 p.s.i. head-mounted main hydraulic cylinders without tie rods and including safety guards

Options:

- Optional part blow-off system to reduce coolant carry-off

- Mist collection system

- Integrated chip conveyor

- Automatic door to accommodate manual load and unload

- Part turnover assembly

- Lift assist crane for collect service

- Offered in electromechanical or hydraulic version

Turnkey Blind Spline Machines and Production Broaching Solutions

Since 1952, Federal Broach has developed turnkey broaching machines and tooling solutions including blind spline broaches. Our custom broaching equipment is engineered to deliver the highest degree of accuracy and repeatability possible. Based in Central Michigan, our company is one of the nation’s leading ISO 9001:2015-certified providers of turnkey blind spline machines and integration systems.

Contact Us Today

Contact us today to learn more about our effective and dependable solutions for your projects.

We look forward to working with you and delivering exceptional results.